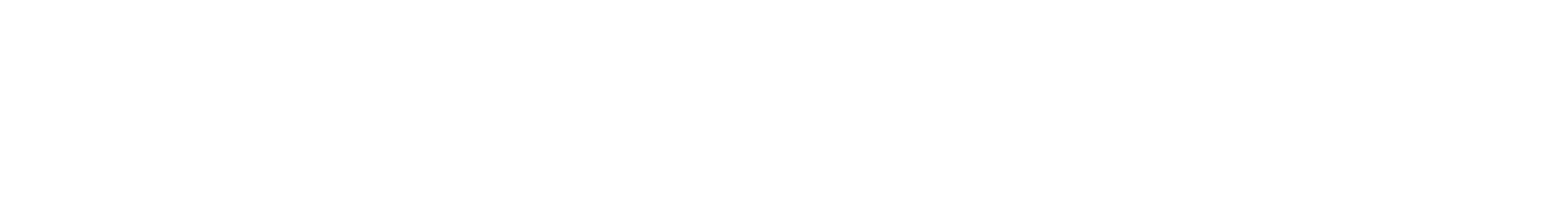

We are thrilled to announce a significant achievement for Trust Your Supplier (TYS) – our continued positioning at the center of Dr. Elouise Epstein’s latest Spider Chart. In a landscape characterized by continual innovation and creativity, TYS stands resiliently at the center, demonstrating our unwavering commitment to excellence in procure tech.

At Trust Your Supplier, we recognize the evolving nature of supplier and risk management within the procurement sphere. Leveraging the transformative capabilities of blockchain technology, our platform offers a comprehensive suite of solutions designed to optimize supplier relationships and mitigate risks effectively.

Our distinguishing features encompass real-time monitoring, comprehensive historical data analysis, and forward-looking predictive insights. By integrating these elements into our platform, we empower enterprises of varying scales to operate with heightened transparency, efficiency, and risk resilience.

As proponents of progress within the procurement sector, TYS is dedicated to pioneering advancements that redefine industry standards. From empowering mid-sized enterprises to supporting multinational corporations, our blockchain-based solution catalyzes transformative change across diverse organizational landscapes.

Yet, our journey is far from over. With each milestone achieved and accolade earned, Trust Your Supplier remains steadfast in our commitment to driving innovation and fostering positive change within procurement.

We extend our sincerest gratitude to our esteemed partners, stakeholders, and industry peers for your continued support and collaboration. Together, we are forging ahead, challenging conventions, and shaping the future of procure tech with integrity and ingenuity.

Stay informed as we embark on this journey of progress and innovation.

Her passion for painting, cultivated since childhood, not only provides solace but also serves as a reminder of the importance of pursuing passions outside of work.

Her passion for painting, cultivated since childhood, not only provides solace but also serves as a reminder of the importance of pursuing passions outside of work.