by Sai Nidamarty, Trust Your Supplier Co-Founder & CEO

Let’s get the cursory narrative regarding the cost of missing data out of the way first.

We have all heard Peter Drucker’s business maxim, “If you can’t measure it, you can’t manage it,”. It is a timeless guidepost of how we run our businesses. By the way, Peter never actually said that, but that is a story for another day.

Then we can turn to the various articles and studies over the past few years reporting that bad or poor-quality data costs the U.S. economy $31 trillion annually. That’s a big number, and so is the finding that 90% of the world’s data was created in the last two years.

The above are all facts and verifiable. But what do they really mean? What does missing or inaccurate data really cost on a practical, everyday level?

There are better venues for a deep analysis than the limitations of an article or blog post. My focus today is to start a dialogue enabling you to transition data strategy from a broad horizon concept to an actionable on-the-ground understanding. In other words, you already know that data is important and that there are consequences for missing or inaccurate data. What’s needed now is to answer the question, what will you do about it?

Data Challenges

In an upcoming webinar, we will convene a panel of industry experts and thought leaders to closely examine data challenges from the following three critical points:

- Data consequence

- Data culture

- 3-Point centralized planning & supplier oversight data framework

When we talk about “data consequence,” we are not talking about broad-stroke generalizations but a fundamental and accessible understanding of impact.

For example, a news article reported that due to a data glitch, Hawaiian Airlines charged dozens of customers “hundreds of thousands of dollars in credit card fees.”

One customer reported being “mistakenly charged more than $150,000,” even though they have a “$10,000 limit on their Hawaiian Miles credit card.”

While another customer was charged $674,000 for airline tickets, others obtained free travel vouchers by paying taxes and associated fees. You can imagine the frustration when the airline canceled their flights.

Beyond a financial mess, the airline’s reputation also took a significant hit. How do you measure that in dollars?

Unfortunately, examples like the one above are not rare or isolated incidences limited to the travel industry. Nor do most cases present themselves in such a prominent and noticeable way. Data quality erosion is an even bigger problem because you may only recognize it once its impact is evident on a larger, less manageable scale.

Creating The Right Culture

Given the volatility of supply networks in the post-pandemic world, it isn’t surprising to hear the C-Suite talk about supply chain visibility, resilience, and risk management.

A recent post by Nick Picone regarding a contentious issue about inflationary price increases between a large, national grocery chain and Frito-Lay underscores the importance of data visibility and transparency.

But how do you get to the point of leveraging tools and technology to move from data darkness to data insight and understanding?

A May 2021 article in Procurement Insights highlighted the importance of creating a data culture starting at the C-Suite level. According to the author, CEOs must “recognize the importance of data beyond a conceptual perspective and see it in a practical bottom-line context.” Citing everything from “customer satisfaction and regulatory compliance” to employee empowerment, they make a strong case for “becoming a data-driven organization.”

The 3-Point Supplier Data Plan

Partner, Mitigate, Comply is at the heart of the 3-Point centralized planning & supplier oversight data framework. Going forward, I will call it the 3-Point supplier data plan.

The 3-Point supplier data plan focuses on providing tools and data for organizations to efficiently partner with trusted suppliers, mitigate risk, and ensure ongoing compliance.

In addition to data consequence and culture, during the upcoming webinar, the panel will get into the specifics of the above 3-Point plan highlighting how you can introduce it to your organization. Register to save your seat.

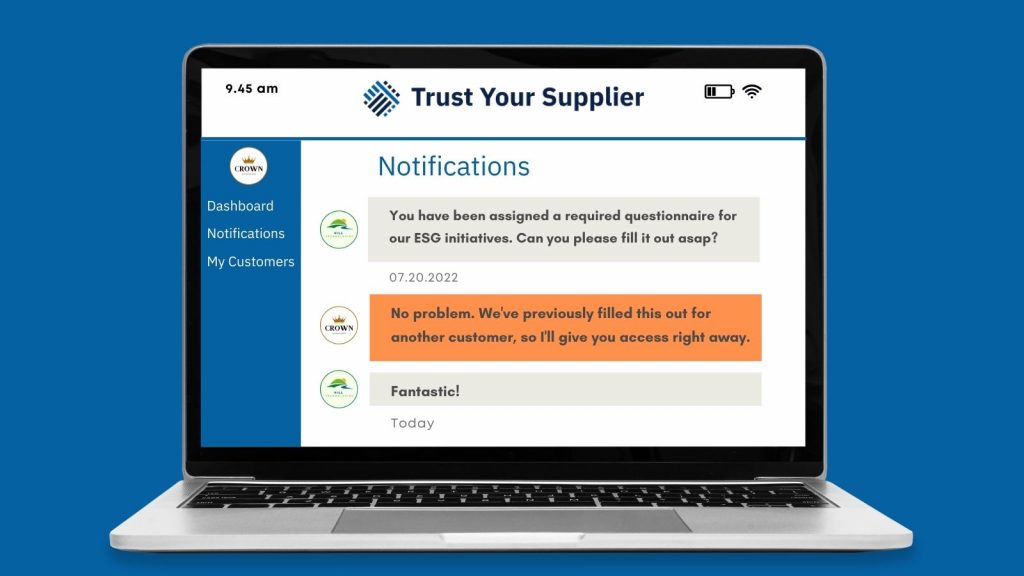

These standardized questionnaires offer additional benefits to buyer teams. The TYS approvals workflow can be customized and automated with each questionnaire. Each answer can be “scored” based on your internal risk threshold. Any answer that does not align with your company’s preferred score will then be directed to the appropriate team role for further review and approval. This allows your team to focus on

These standardized questionnaires offer additional benefits to buyer teams. The TYS approvals workflow can be customized and automated with each questionnaire. Each answer can be “scored” based on your internal risk threshold. Any answer that does not align with your company’s preferred score will then be directed to the appropriate team role for further review and approval. This allows your team to focus on