One Supplier, Four Truths: Why Supplier Data Is a Cross-Functional Problem

Picture this scenario:

A mid-sized automotive parts manufacturer is onboarding a new supplier for a critical component. Finance has already set up payment terms and verified banking details. Procurement has completed the relationship assessment and signed off on the contract. Compliance is still waiting on three certifications. ESG hasn't been looped in at all.

Six weeks later, the supplier is active. Purchase orders are flowing. Everything looks fine.

Then an audit surfaces a gap: the supplier's environmental certifications don't meet the standards your largest customer just updated in their vendor requirements. ESG flags it. Compliance escalates it. Procurement is caught off guard. Finance has already processed four invoices.

Nobody did anything wrong. Every team did their job.

The problem was that nobody was working from the same picture.

The Same Supplier, Seen Four Different Ways

In most organizations, a supplier isn't a single entity. It's four different entities, depending on who you ask.

In most organizations, a supplier isn't a single entity. It's four different entities, depending on who you ask.

Finance sees a payment counterparty. They care about banking details, payment terms, tax documentation, and currency risk. Their primary concern is making sure money moves to the right place, compliantly, and on time.

Compliance sees a regulatory exposure. They care about certifications, contractual obligations, industry standards, and audit readiness. Their primary concern is ensuring the organization isn't exposed to legal, regulatory, or reputational risk through its supplier relationships.

ESG sees a sustainability partner—or liability. They care about carbon footprint, labor practices, ethical sourcing, and environmental certifications. Their primary concern is ensuring supplier relationships align with the organization's sustainability commitments and increasingly stringent reporting requirements.

Procurement sees a strategic relationship. They care about performance, pricing, reliability, and long-term partnership potential. Their primary concern is ensuring the supplier delivers value and supports business continuity.

Same supplier. Four valid perspectives. Four different sets of questions. Four different definitions of "what we need to know."

This isn't a dysfunction. It's actually appropriate. Different functions exist to manage different types of risk and value. Of course they see suppliers differently.

The problem isn't the different perspectives. The problem is what happens when those perspectives operate in isolation.

What Goes Wrong When Everyone Has Their Own Version of Truth

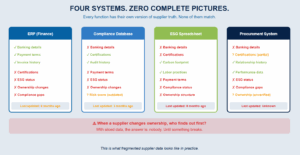

In many organizations, each function manages supplier information independently. Finance has their records in the ERP. Compliance maintains a separate database of certifications. ESG tracks sustainability data in spreadsheets. Procurement manages relationships in their own system.

The result: four versions of the same supplier. Each one partially complete. None of them fully trusted.

When Finance updates banking details, Compliance doesn't automatically know. When a certification expires in Compliance's records, Procurement isn't alerted. When ESG discovers a supplier has changed their manufacturing processes, Finance is still paying invoices against outdated contract terms.

In a manufacturing environment, this fragmentation creates cascading risks:

A tier-1 supplier changes ownership. Finance updates the banking details for the new entity. Compliance doesn't know. They're still validating certifications under the old entity name. Procurement is negotiating a contract renewal with the old contact. ESG has no visibility at all.

Three months later, a regulatory audit reveals the supplier's quality certifications lapsed during the ownership transition. Nobody caught it because nobody had the complete picture.

This isn't hypothetical. It's a pattern that plays out across industries, from manufacturing to energy utilities to consumer goods, wherever supplier data is managed in silos.

The cost isn't just operational friction. It's regulatory exposure, payment fraud risk, sustainability reporting gaps, and supply chain disruptions that could have been prevented.

The Wrong Solution: Forcing Everyone to See Suppliers the Same Way

The instinctive response to this problem is standardization. Build one system. Force everyone to use it. Make procurement own supplier data across the organization.

It sounds logical. It rarely works.

Because Finance doesn't want to navigate procurement workflows to find a tax document. Compliance doesn't want to dig through payment history to find certification expiration dates. ESG doesn't want to submit change requests through procurement to update a carbon footprint score.

When you force functions to work in a system designed for someone else, one of two things happens: they comply reluctantly and use it badly, or they quietly maintain their own records anyway.

Either way, you're back to fragmented data. Just with an extra layer of process friction on top.

The goal isn't to make everyone see suppliers the same way. The goal is to make sure everyone is looking at the same underlying truth.

What "Single Trusted Foundation" Actually Means

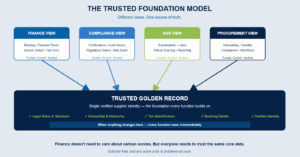

The modern approach to supplier data isn't one system that does everything for everyone. It's one trusted core that every system draws from.

Think of it as a hierarchy of supplier information:

The foundation: Core supplier identity—legal name, ownership structure, registration details, tax identification, banking information. This data doesn't change often, but when it does, everyone needs to know immediately. This is non-negotiable shared truth.

The functional layers: Each team builds their view on top of that foundation. Finance tracks payment terms and transaction history. Compliance manages certifications and regulatory requirements. ESG monitors sustainability metrics and labor practices. Procurement manages performance and relationship history.

The key is that each functional layer connects back to the same core record. When ownership changes, every function sees it. When a critical certification lapses, it surfaces across the organization—not just in the compliance database.

Finance doesn't need to care about carbon footprint scores. Compliance doesn't need to care about payment terms. But everyone needs to trust that the supplier they're looking at is the same supplier everyone else is looking at - verified, current, and accurate.

This is what separates organizations that manage supplier risk proactively from those that discover problems during audits.

What This Looks Like in Practice

Consider a global manufacturing company managing 500+ suppliers across multiple production facilities. Their supply chain spans tier-1 component manufacturers, tier-2 raw material suppliers, and specialist service providers.

Under the siloed model, their supplier data looks like this: ERP records that are accurate for finance but six months behind on certifications. A compliance database that's current but only accessible to two people. ESG data that lives in spreadsheets updated quarterly at best.

When a regulatory change requires updated environmental certifications from all tier-1 suppliers, the compliance team has to manually contact each supplier, track responses in email, chase down documentation, and reconcile everything against the ERP. The process takes eight weeks and involves five people across three departments.

Under a unified model, the same process looks very different. Suppliers maintain their own profiles in a shared network. When certification requirements change, automated notifications go to every affected supplier simultaneously. Responses update in real-time. Finance, Compliance, ESG, and Procurement all see the current status without making a single phone call.

Eight weeks become days. Five people become one workflow.

The difference isn't just efficiency. It's confidence. Every function makes decisions based on the same verified data, not its own version of it.

The Business Case Is Cross-Functional

When supplier data quality is treated as a cross-functional discipline rather than a procurement problem, the benefits compound across the organization:

Faster onboarding: When core supplier data is verified once and shared across functions, each team isn't starting from scratch. Onboarding cycles that take weeks can be reduced to days.

Safer payments: Finance operating from verified, current supplier records dramatically reduces exposure to payment fraud, duplicate payments, and banking detail errors—one of the most common and costly supplier fraud vectors.

Cleaner audits: When compliance data connects to the same foundation as procurement and finance records, audit preparation stops being a scramble. Documentation is current, traceable, and consistent across functions.

Better risk management: Real-time visibility into certification expirations, ownership changes, and compliance gaps means organizations catch problems before they become crises, not after.

Stronger ESG reporting: As sustainability reporting requirements become more rigorous, organizations need supplier data they can actually stand behind. That requires a verified foundation, not a spreadsheet updated once a year.

Building for the Whole Organization

The companies that manage supplier relationships most effectively aren't the ones with the most sophisticated procurement teams. They're the ones that recognized supplier data as an organizational asset—not a departmental one.

They built systems that give every function the view they need while ensuring everyone is working from the same trusted core.

At Trust Your Supplier, this is the principle our platform is built around. A single, verified supplier record—what we call the Trusted Golden Record—that different functions can access through their own lens without compromising the integrity of the underlying data. Finance sees what Finance needs. Compliance sees what Compliance needs. ESG and Procurement see what they need. But everyone is working from the same verified foundation.

The result is an organization that moves faster, manages risk better, and makes decisions with confidence, because everyone is finally looking at the same supplier.

Interested in how Trust Your Supplier helps cross-functional teams work from a single source of supplier truth? Take a product tour or reach out.